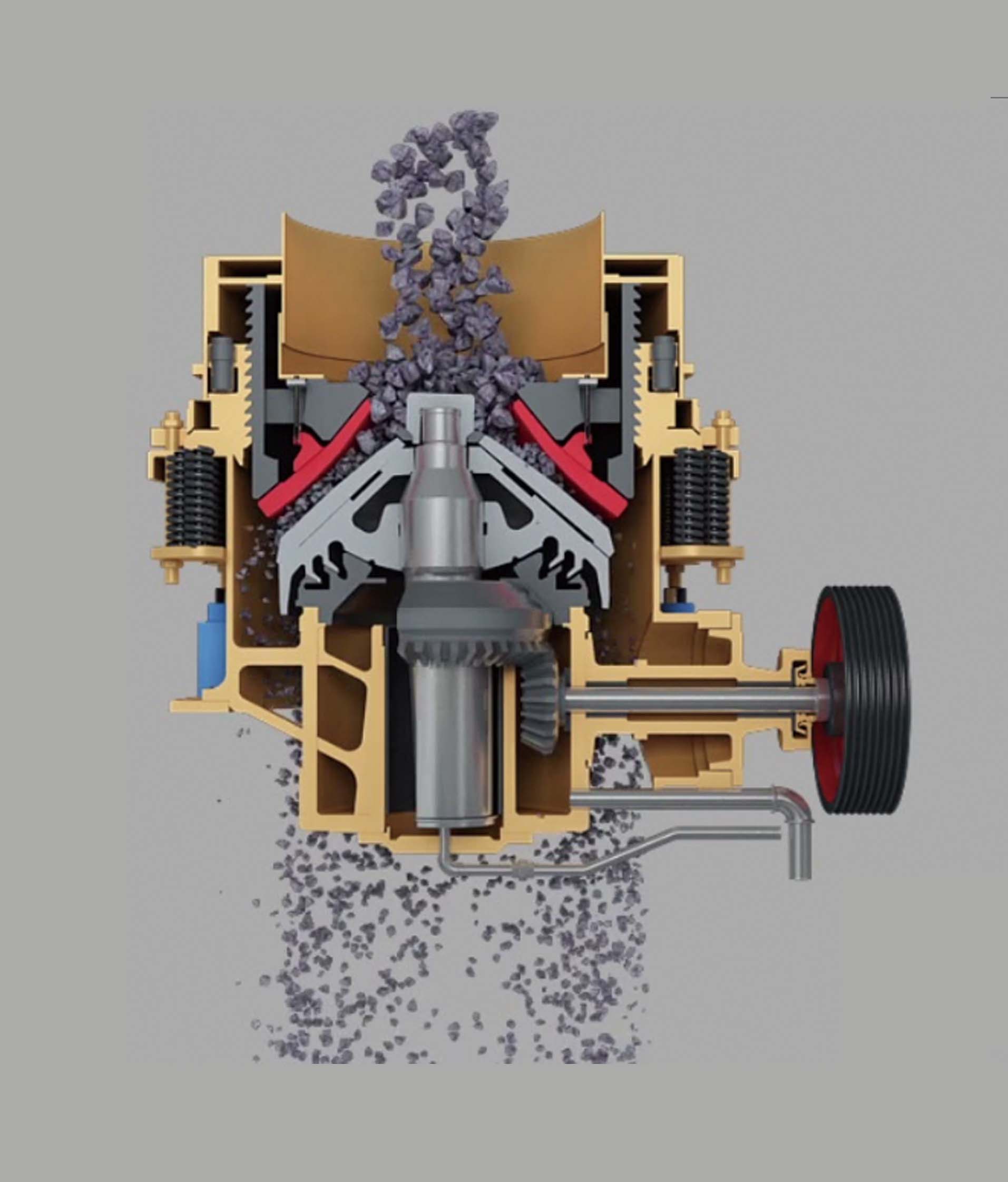

Peças de desgaste de qualidade incluem manganês para a linha de britadores de mandíbulas, incluindo mandíbulas, volantes, estruturas principais e placas de bochecha

✅ Dentes largos (WT)

✅ Ondulado (C)

✅ Corrugado Grosso (CC)

✅ Dentes Afiados (DA)

✅ Serviço Pesado (HD)

✅ Ultra-espesso para serviço pesado (UT)

Item nº :

FG0015256Origem do produto :

ChinaCor :

OriginalTempo de espera :

10 daysContato :

+86 18820104928A FGMachinery oferece uma seleção abrangente de placas de mandíbula de manganês em vários graus, adaptadas para atender às demandas específicas da sua aplicação.

A escolha do tipo certo de manganês é fundamental — isso não só aumenta significativamente a vida útil das peças do britador, como também melhora a relação custo-benefício geral das suas operações.

Opções de perfil de dente disponíveis

Dentes largos (WT)

Ondulado (C)

Corrugado Grosso (CC)

Dentes Afiados (DA)

Serviço Pesado (HD)

Ultra-espesso para serviço pesado (UT)

A placa de mandíbula ideal — juntamente com o projeto correto da câmara de britagem — depende do seu contexto operacional, seja na extração de rochas, mineração de minério ou reciclagem de materiais.

Graus de liga e ajuste de aplicação

M1 (Liga Padrão): Projetado para alta resistência a impactos e uso geral. Especialmente eficaz na trituração de rochas duras e não abrasivas, pois endurece bem no local.

M8/M9 (ligas premium): projetadas para ambientes de alta abrasão. As ligas M8/M9 oferecem resistência ao desgaste significativamente maior, mas têm tolerância a choques ligeiramente reduzida em comparação com a M1.

Para otimizar o desempenho, a melhor classe e perfil da placa de mandíbula devem ser selecionados com base nas características do material de alimentação — como índice de abrasão da rocha (IA) e índice de trabalho (IW) — bem como no atrito de alimentação e no perfil de gradação.

Por que nossos componentes de manganês se destacam

Projetado para flexibilidade em diversas condições operacionais

Projetado para maximizar o tempo de atividade e reduzir o desgaste

Otimizado para redução eficiente de material e maior rendimento

Construído para uma longa vida útil operacional e desempenho confiável

Deixe-nos ajudá-lo a selecionar a câmara de britagem e o grau de manganês corretos — a experiência de líderes do setor como a FGMachinery confirma que a combinação adequada de liga e perfil reduz drasticamente o tempo de inatividade e aumenta a produção.

Próximo passo

Para recomendações personalizadas, entre em contato com seu representante local da FGMachinery — ele ajudará a identificar o padrão ideal de placa de mandíbula, o grau de liga e a especificação da câmara de britagem para sua aplicação.

Informe-me se você quiser um gráfico comparativo de casos de uso de padrões de dentes ou projeções de vida útil de ligas. Terei prazer em criar um!

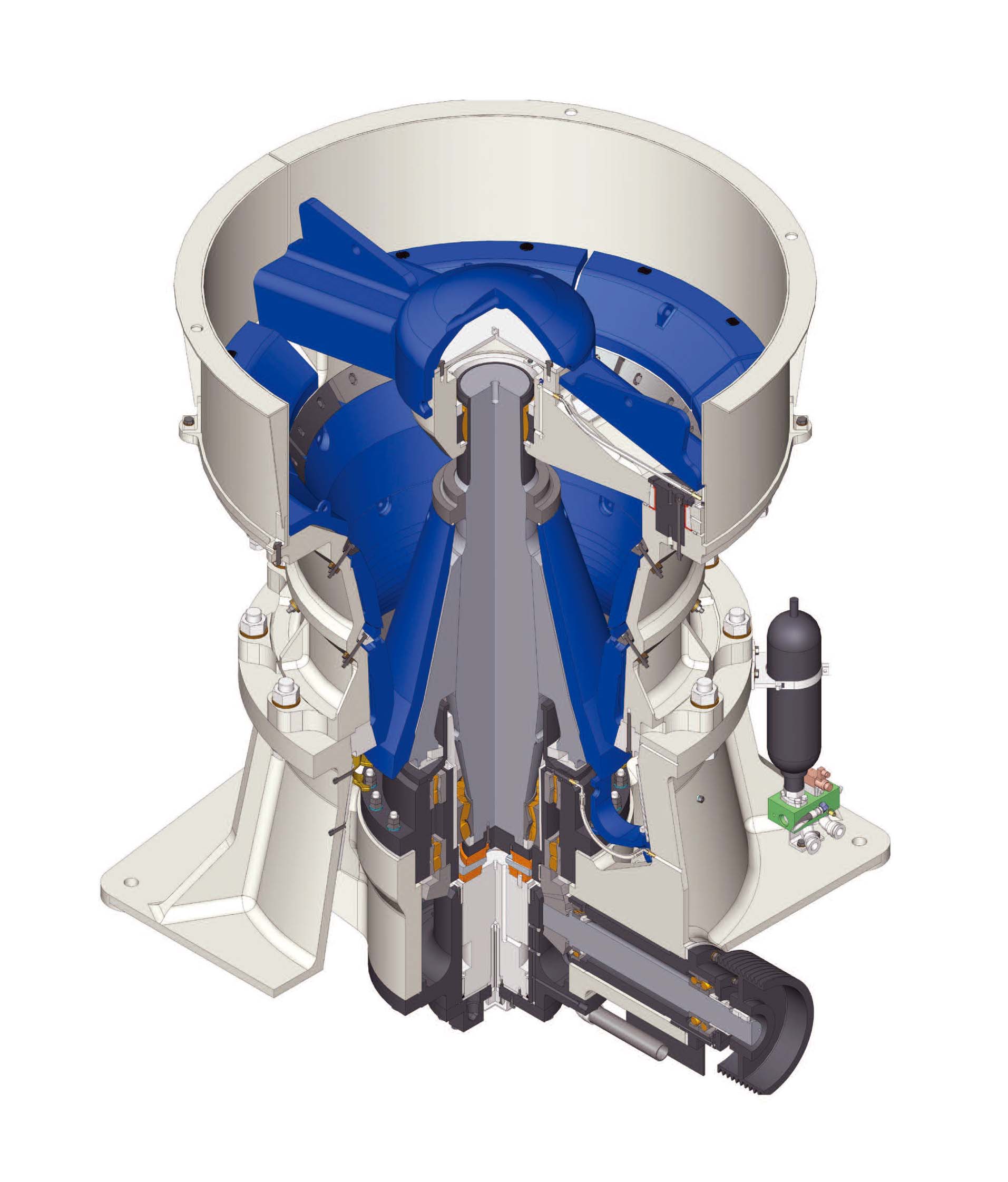

Ajuste preciso: O anel de ajuste permite o controle preciso da folga do britador, possibilitando o dimensionamento ideal do material e melhorando a qualidade do produto.

Construção Robusta: Feito de materiais de alta qualidade, o anel de ajuste do britador cônico foi projetado para suportar cargas pesadas e resistir ao desgaste, garantindo um desempenho duradouro.

Estabilidade aprimorada: Seu design proporciona maior estabilidade durante a operação, reduzindo vibrações e melhorando a eficiência geral do processo de britagem.

Tempo de inatividade reduzido: O anel de ajuste do britador cônico foi projetado para fácil instalação e ajuste, minimizando o tempo de inatividade durante manutenção ou alterações nas configurações.

Desempenho consistente: Ao manter a folga adequada, o anel de ajuste do britador cônico garante um desempenho de britagem consistente, resultando em uma saída uniforme.

Compatibilidade Versátil: Compatível com vários modelos de britadores, o anel de ajuste do britador cônico pode ser personalizado para se adaptar a diferentes aplicações, melhorando sua usabilidade.

Custo-benefício: A durabilidade e a eficiência do anel de ajuste do britador cônico ajudam a reduzir os custos de manutenção e prolongar a vida útil do britador, proporcionando um melhor retorno sobre o investimento.

Características da tampa de ajuste do triturador cônico

PORFILO DA EMPRESA

Guangzhou Future Green Machinery Co., Ltd. fundada em 2021, nosso escritório está localizado em Guangzhou. Somos uma empresa inovadora. A empresa sempre garante o avanço tecnológico do equipamento: maior eficiência, menor consumo de energia e mais proteção ambiental. Nossos principais produtos são equipamentos de britagem, equipamentos para fabricação de areia, máquinas para fabricação de pó, equipamentos de alimentação, máquinas de suporte para fábricas de cimento, etc. A empresa continuará a explorar, pesquisar, desenvolver e inovar em novos campos, enquanto ajuda constantemente os clientes a resolver várias dificuldades e problemas, e a criar maior valor para os clientes. Guangzhou Future Green Machinery Co., Ltd. fundada em 2021, nosso escritório está localizado em Guangzhou. Somos uma empresa inovadora. A empresa sempre garante o avanço tecnológico do equipamento: maior eficiência, menor consumo de energia e mais proteção ambiental. Nossos principais produtos são equipamentos de britagem, equipamentos para fabricação de areia, máquinas para fabricação de pó, equipamentos de alimentação, máquinas de suporte para fábricas de cimento, etc. A empresa continuará a explorar, pesquisar, desenvolver e inovar em novos campos, enquanto ajuda constantemente os clientes a resolver várias dificuldades e problemas, e a criar maior valor para os clientes.

ENTREGA DE PACOTES

ESTUDOS DE CASO DE VÁRIOS SETORES

Emergency:

+86 18820104928Direitos autorais

© 2025 Guangzhou Future Green Machinery Co., Ltd. All Right Reserved.

SUPORTADO POR REDE

XML política de Privacidade

SUPORTADO POR REDE

XML política de Privacidade